Wood fired ovens construction details

Wood fired ovens construction details for building. Plans to build own wood burning brick ovens, heat expansion & heat differences in material, structural measurements.

Wood fired ovens hearth, dome, vent, flue, chimney, heat expansion, mortars, thermal insulations and oven building plans.

For a wood burning oven to work properly and efficiently there are few rules to be remembered and applied in practice. Once you go according these your pizza wood oven in action should be fine. I wrote "should be" because, e.g. if you forget to add a cement into mortar or work fast willy-nilly, you may miss some things.

I do not intend here to say we have to use common sense, nobody is perfect. But if you are like me who enjoys doing things patiently and do not experiment too much with untested ideas the happiness will arise from this endeavor, after all we are not making a spy satellite. Stick with principles below and you are fine.

Wood oven building details

I use both Metric & Imperial measurements, swapping them makes it fair. Enjoy. Even though this is not too important as not much measuring goes around, in building wood ovens all is done mainly on brick count, you won't feel neglected. But still here is length units converter if it's needed some day, or convert-to.com provides many practical unit converters for quick-online use.

Points written in here fit to an average sized wood burning oven for backyard garden or inside the house. Making pizza at first, then in the same accumulated heat energy a big roast with veggies and after still baking breads or cakes with 10 friends, wood oven of internal dome size:

82 - 90cm x 90 - 100cm (32 to 35inch x 35 to 39inch) will do perfectly. If you had a restaurant wood pizza oven in mind, ovens with internal dome sizes of:

4ft x 5ft (1.22m x 1.5m) or 5ft x 6ft (1.5m x 1.8m) similarly but a bit more larger if domes are in diameter ( diagram picture for rectangular barrel brick oven design versus round brick oven ).

Rectangular barrel dome Vs. round oven dome.

Which dome is better ...?

I receive many emails with questions; Which dome shape is better for cooking, easier to build, more economical to fire, which holds the heat longer, will it take 3 hours to heat up :o), which dome lasts long? Which one should we build, rectangular floor dome pizza oven or igloo round floor dome oven?

People also ask more serious questions; Why isn't our oven hot enough? Why isn't it holding heat, in floor or in the whole dome, etc. Both domes can be superb if you come into the simple terms with "how to design and build ovens" factors. If needed, I created new page focused on these questions and others with logic, on what to do before and while building ovens.

Refractory mortar:

Building mortar and refractory mortar are not the same. Refractory fire clay based mortar is not used as the ordinary mortar used by bricklayers. House building mortar joins bricks by keeping them separated. In wood ovens, refractory mortar should strictly be used only where flat firebrick joint is impossible. More on refractory mortar recipes and use.

General purpose building mortar:

This is not refractory mortar, it's mortar for laying ordinary building bricks, a house bricks, like those bricklayers use:

6 : 1 : 1 - Sand, Portland cement and Lime. Lime in brick laying mortar keeps water in, making the mortar soft for longer, giving more time for work. About 3 times longer till it sets. Or you can mix mortar without the lime: 4 : 1 - Sand and Portland cement.

Concrete cladding:

Cladding is minimum 5cm - 2" thick concrete layer applied over the firebrick dome of any style. Concrete oven cladding is very quick and easy to do and amount or cost of material cladding requires is very low. In contrast, usage degree of every oven with extra dense layer is much more higher. Home oven with 11.5cm - 4.5" firebrick wall and 5cm - 2" cladding layer will heat up into pizza temperature, 350°C - 662°F and higher, in under 1-1/2 hour (one and half hour.) More about oven cladding and recipe.

Refractory heat insulations:

Refractory insulation is light in weight protective layer applied on top of the dense cooking chamber or under to make oven more efficient and economical. Heat naturally tends to climb up so purpose of insulation is to stop loosing heat energy from the fire disappearing the wrong way mainly throughout the top or sides. Insulation also stops the heat to warm up oven's outside decorating walls. Variety of insulation materials can be used to insulate wood ovens. Heat insulation is similar to honey comb effect, the actual material particular insulation consists of is there to create air spaces, and separated air spaces (like in ceramic fiber insul. tile layer on space shuttle) are the best insulation. More about heat resistant insulations and recipes and another page specifically about vermiculite insulation.

I like the outside barrel or igloo look!

If you like the igloo character you can cover rectangular dome with heat insulation formed into the igloo or half cylinder shape giving your oven a simple weather render finish on chicken wire. Heat resistant insulation is light in weight and soft therefore it absorbs dome heat expansion movements thus preventing creation of visible bad cracks on outside. You can use low cost and still very good insulation materials (with same or better properties then Vermiculite or Perlite), and yes you can add more of it on top to make your oven more efficient and evenly heated for much longer roasting and baking times.

I'd like to get back to these cracks and use of the insulation because it's important; there can be nothing worst than seeing your oven cracking on outside including the front decoration. Here we deal not only with heat expansion but also with 'heat differences in materials'. Heat insulation assists as layer between the solid dome and the outside solid deco finish of all kinds. Dome is solid it expands on heating no matter what, if the outside oven structure was bonded to it, or it's enough if it touches it, it will get pushed as well. Break/separate these two with the insulation layer in between for instance, insulation is softer and so will deal with the impact. I receive many heart braking emails making me sad reading that someone who didn't know this is in such situation.

If you want to built at home a real nice chef oven for yourself always incline to a brick dome job. Do not prefabricate/cast your dome, such domes develop cracks in the larger parts and start pealing if not dome properly. If you prefer having and cooking in a prefabricated oven, buy one instead, as there are high quality products on the market and also prefabricated oven products in kit forms. Home made larger block parts are always affected by heat differences in material. This work needs many tests initially. Firebricks are made out of clay and in manufacturing process are fired/stabilized in industrial kilns. Standard 26% alumina content firebricks are meant to withstand in 2400°F - 1320°C continuous use. Brick dome is structure made of many small fragments, with heat expanding everything can nicely move without developing major cracks. Industrial furnaces are not put together out of larger cast segments because with only a few blocks it's not effective down the road. Spare parts would be costly in more aspects. Clay/mud in firebrick form is the best and natural refractory, and of course firebricks last very long time. More physical properties' numbers for all firebrick grades from 18% to 40% Alumina content in all fire brick bodies. Also soapstone is commonly used/ Look into these complete soapstone thermal data with mass calculator.

A few pictures of oven being completed.

Dome internal height (Vault) to entry door height ratio must be properly calculated. For best achieved burning in your ovens, this is very important to have both height measurements right. When you have your job done, you want the fire to burn well inside. This ratio is 62% to 64%. Most precise example for home oven:

Entry door height: 10 inch (25.4cm)

Vault height (internal): 16 inch (40.6cm).

In actual fact dome is a lot lower one could imagine looking at the built oven from the outside. Highest ceiling point, Vault, must be this low. Heat from the fire stored in the massive walls radiates back onto cooking meals, plus the chamber becomes smaller in volume concentrating important steam thus creating good baking conditions.

If you asked me why is it this percentage value I would tell you in the history, when you look at those many best working wood burning brick ovens with different floor surface volume and tested their measurements, you will get an average value of this same ratio. Do not change it too much or do not experiment with the door height too much. It's like with our nature, if you alter it too much, it will turn against you.

What would need to be done if you were about to make the entry smaller, another source of oxygen inlet would have to be introduced into firing chamber to achieve a normal fire burning.

If you made the door bigger, the heat would be escaping out through the door upper level making your oven less economical and harder to use. Perhaps your eyebrows would shrink after a while too :) Hair on my right arm is always shorter, looks as undeveloped, because I like to quickly stick it in, grab something to take it out and eat it then (backwards to everyone to properly test their salivary glands) or decently put something inside.

Entrance on fired wood ovens is built much lower then doors for instance on fire places. Then there is the space between the vault and the flue or air vent level (exhaust) level where is the climbing heat from the fire held, absorbed into walls and not to be wasted.

Brick wood burning ovens use 75% of heat energy from the fire and 25% is leaving out trough the chimney. Quite a good conductivity isn't it? At times I hear that cladding over the brick dome causes long heating up time but of course it is not the case, unless 10 minutes were the consideration. It is the firing/heating up tactic wrong and not concrete-cladding if firing takes any longer than 1-1/2 hour. If you wanted it may take only 1 hour to reach pizza temperature in home ovens with cladding. Although rather than the aggressive heat up I prefer moderate heating which takes me 1 hour and 30 minutes very easily, so after pizza (if there was a pizza time) I can still cook long time in the heat accumulated.

Besides cooking always only pizzas would be rather extremely boring and not fun!!! Oven with cladding will give you 5 hours roasting/baking time without any firing after pizza temperature dropped down, and much longer post baking fruit drying time. Heat absorbing mass is totally needed for bigger roasts like big turkey, leg of lamb etc., for quality roasting or baking enough heat energy stored is absolutely essential. How about to bake bread or cake after roasting and then dry fruits and halved tomatoes for 24 hours, great hmm? Cladding offers that. To be stable even every quality Commercial pizza oven and Conveyor ovens use dense layers on the hot face inside the oven. That is exactly how these ovens are built. Some ovens, not only the large production ovens, have double brick level size domes (not 2x 11.5cm but length-wise 2x 23cm ... not 2x 4.5" but 2x 9" brick side.)

Don't worry about thicker dome walls if you only want oven entirely for pizza, pizza is done while red embers still radiate in the dome, just give more mass to the floor so it won't drop downwards the high pizza temperature fast after hot embers were swept to sides.

Fire brick heating stoves with a good drought labyrinth absorb 90% of energy from the fire and only 10% is wasted, what a great technology or system!

Now fireplaces, in these we actually use only 10% of the energy radiating out from the fire into a room and 90% of the heat runs out through the chimney.

For the oven's hearth floor lay refractory fire bricks on the sand-bed or on a thin layer of 1:1 fire clay ( fire clay explained ) and sieved sand to remove all pebbles (half bucket of fine sand is needed for the job, without any little stones, otherwise if a small pebble is under a firebrick you cannot level it nicely), mixed with water into a paste. Spread the clay sand mix onto moist water slab with zigzag plastering trowel tool, the one which has the square teeth on its edge. Without using joining mortar place bricks on closely, one next to another. As you go use a wooden or rubber mallet to level the bricks evenly to a smooth surface. Hearth bricks have to be laid on at least 2 days after the concrete slab is dry - cement curing, which is reinforced using higher grade metal mesh and rods.

If you contemplate your own challenging project to construct the oven by your self - whether big or small, wood oven with an interesting looking brick decoration or a very simple oven which has a quality made dome placed low set right on the ground, and a nice front entry brick arch, with chimney or without it - consider using complete help with all construction stages from my open source 'Swishy oven' building Tutorial WorkShop on the CDrom. This cd will direct you through the whole job to get your oven right on the first time, with it you'll know clearly in advance what you'll do each building day or stage.

New in the Cdrom Log:

1. wood fired oven WorkShop - includes 370 pictures for all building stages

2. "Equivalent materials and sources" folder, for those who for any reason can't locate or buy refractory cements, fireclays, refractory mortars, firebricks, heat insulations (several substitutes and preparations described, how/where to get them and working with them, good readin' - print it out to bed.)

3. "in Dome Photographs" folder (large photos of fires and meals in the wood fired oven.)

WorkShop tutorial content and how to get hold of it page.

* Maybe you look here for someone who can build a wood oven for you, then please ask me first (just rising awareness).

Video of MTo pizza oven / Ferrari design, by Jim (hand-picked stones collected for the construction in the nature surrounding his place.)

Thank you for watching. Enjoy your ovens building, firing up and then the cookindo grandissimo!

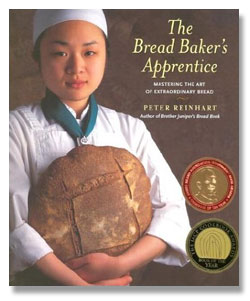

After pizzas use the stored heat energy for baking breads

In fact you can bake for 4 to 6 hours reloading batches in the oven (including slow long time roasting at baking temperatures.) My favorites are whole mixed grains breads, Sour Dough and Turkish breads, sweets of course. It's a good idea to own a proper book about baking strategies, I ordered this one from eBay and I'm enjoying reading it ever since:

To order this book click here

To order this book click here

Great as present, or must have DIY Book by Peter Reinhart: "The Bread Baker's Apprentice".

by Rado Hand