The flue vent and hot-air passage. How Wide & Deep are they?

What is the optimal flue width and depth? This is one of the important questions, especially in indoor ovens. Say that the entry opening to the oven is 10″ – 245mm high and the width isn’t crucial (but most commonly I make the entry 400mm = 15-3/4 inches wide.) The size of the flue, which is the boxed space around and above the entry surface area (also called hood or air vent or just a box) has to be spacious enough so completely all the exhaust fumes, 100% of the hot air gases exiting the oven, all gets directed only upwards into the hot air passage and through the chimney they travel out.

What is the optimal flue width and depth? This is one of the important questions, especially in indoor ovens. Say that the entry opening to the oven is 10″ – 245mm high and the width isn’t crucial (but most commonly I make the entry 400mm = 15-3/4 inches wide.) The size of the flue, which is the boxed space around and above the entry surface area (also called hood or air vent or just a box) has to be spacious enough so completely all the exhaust fumes, 100% of the hot air gases exiting the oven, all gets directed only upwards into the hot air passage and through the chimney they travel out.

It’s not really the chimney as we know it because there aren’t the draft conditions present because that’s not needed in outdoors ovens system with the straight up hot-air passage. These designs function completely properly without the draft (but still, if there was the pull in a chimney then it’s fine too).

HOWEVER :

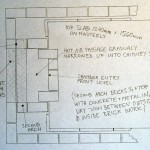

Basically, this flue needs to be wider at least by 1″ – 25mm on each side than is the actual entrance width (if it is even wider than that, it’ll be only for benefit – less heat radiation onto the hood box sides plus more room for work on the working-surface area or to just rest elbows on. This is why I call the surface a “pot resting surface”.) Because it is practical, I make it no less than ~ 5″ = 130mm wider on each side. In the new MTo design this outside hood box is 715mm = 28.15 inches wide internally from side to side. The total width of the whole surface makes it roughly 6-1/3″ – 160mm wider @ each side. This flue box also nicely blocks a possible wind blowing into the oven from the outside and that aspect is very practical and effective.

Basically, this flue needs to be wider at least by 1″ – 25mm on each side than is the actual entrance width (if it is even wider than that, it’ll be only for benefit – less heat radiation onto the hood box sides plus more room for work on the working-surface area or to just rest elbows on. This is why I call the surface a “pot resting surface”.) Because it is practical, I make it no less than ~ 5″ = 130mm wider on each side. In the new MTo design this outside hood box is 715mm = 28.15 inches wide internally from side to side. The total width of the whole surface makes it roughly 6-1/3″ – 160mm wider @ each side. This flue box also nicely blocks a possible wind blowing into the oven from the outside and that aspect is very practical and effective.

Now, the arch holding the back-side-wall of the hood/chimney doesn’t need to be exact, it will perfectly do if it’s 2 or 3 inches – 5mm to 75mm wider, 3 inches – 75mm higher next the entrance. This MTo is designed the way it accommodates any style or type of refractory part (not just the itself MTo firebrick design chamber) instead an igloo round floor, or square, or prefabricated/kit purchased domes fit it smoothly. The height of the decorative arch in the outer front facing wall also can be slightly changed; however don’t make it too much higher (if you wanted to make it higher say by 10cm – 4″, then increase also the depth sizing marginally.)

Now, the arch holding the back-side-wall of the hood/chimney doesn’t need to be exact, it will perfectly do if it’s 2 or 3 inches – 5mm to 75mm wider, 3 inches – 75mm higher next the entrance. This MTo is designed the way it accommodates any style or type of refractory part (not just the itself MTo firebrick design chamber) instead an igloo round floor, or square, or prefabricated/kit purchased domes fit it smoothly. The height of the decorative arch in the outer front facing wall also can be slightly changed; however don’t make it too much higher (if you wanted to make it higher say by 10cm – 4″, then increase also the depth sizing marginally.)

How deep should the flue/hood be?

* That was for the flue hood width :

A more IMPORTANT component to emphasize is the depth-measure of the hood box! It should be minimum 13″ – 33cm internally (13 inches and deeper. 15″ – 38cm ideal in indoors ovens). “Deeper”, which is the length between the inner side of the front facing wall and the oven entry point. Because the hot air exits under not too sharp radius the flue simply needs to be this deep.

In here as per the internal depth aspect, as mentioned above, relates also the minimum height of the deco wall entrance arch. The formula is; the deeper the smoke collection hood the higher the from wall deco arch can be.

Then this flue can be gradually narrowed upwards. Then roughly 2 feet – 60cm + from the actual outer top level of the oven, only then a chimney pipe or chimney liner can be connected, if needed because most often the simple brick work will do normally. It is always wise to get the widest diameter sold (I attached you one high quality hard s/steel fabricated type with a cap I get manufactured at times. It looks marvelous, speeds up work. Just keep in mind that children should not be able to reach it as it gets quite hot. You can buy flexible chimney liner lengths or kits as well and easy DIY guide with them.)

Any sheet metal manufacturing business will make these to any specific size. Usually the more pieces are ordered equals to better price per each.

It is a simple principle easy to understand, notice the stage among the MTo building sequence pages. Most often I build the flue (box, hood) out of clay house bricks. But if there is not enough room for making the depth or width, instead of thick house bricks, a box out of a corrugated iron sheet or copper sheets, etc., with some nice rivets or some art work on, will add a nice character for the oven too. It is important in the first place that the correct functionality will be maintained.

** I don’t know why but, sadly very-often people make it very small, because they saw how someone else’ve done that. Or they install there only a stainless steel pipe, perhaps thinking this pipe will suck in and drag out through its whatever diameter all the exhaust fumes. Not so! Even a 1′ – 300mm pipe just on the outside above the exhaust area of the chamber isn’t nor won’t be enough to collect all smoke or the heat (unless a strong draft was introduced, although it = who would want to force vacuum the precious heat out from the oven that way?!).

But back to the box size-depth; If this is too small like that what happens, the smoke gets into the room or eyes cause not all exhaust fits in there and the walls get heated. In such a case, this is exactly when ovens get carbon soot color on the outside just in the outer front decoration above the decorative entrance arch.

* Did I mention that both this box and the chimney are very easy to make? I think I should if I did not.

Rado

Respond to the The flue vent and hot-air passage. How Wide & Deep are they? article:

28 Comments

Sorry, the comment form is closed at this time.

How tall may the chimney be and still draft properly. I am building an outdoor kitchen attached to my house. The roof over the oven will be about 3.0 meters at the chimney location. The chimney must pass through at this height at extend at a meter more, or a total of 4 to 4.2 meters – 13.12 to 13.78 feet. Will that height cause a draft problem? If so, what can I do to solve that?

Thanks,

Paul

Decorah, IA USA

By Paul

Hi Paul,

Thanks for the note.

In this system – in a sense of influencing the oven’s performance – the height/length of the chimney does not play any role. This is due to the fact that the chimney vent is not inside the fire-brick firing/cooking chamber. The chimney connects only to the hood, which is the box located in the front/outside the oven. In other words, the oven will perform exactly the same way no matter whether the chimney is 1 foot ~ 30cm or much taller than 16 ft = 4.9 meters.

Internally the chamber also does not use the draft from chimney. The draft you achieve however will assist to collect drag upwards and outside all fumes exiting the oven. Install any chimney-pipe length as you would also with a large fireplace or wood heater. Main is that the whole vent outside of the oven is spacious enough (in width and depth also), just like the measurements in this article or bigger, so it safely keeps 100 percent of all those hot air fumes before they go into the chimney passage.

Did this help you? Is your chimney pipe insulated, what diameter size pipe? The wider it is the better.

Thanks for converting it to Metric for me :-) I actually function in both systems automatically for many years now.

Warm regards.

By Rado

Hey Rado – I’m planning to build a pizza / bread oven this summer and really looking forward to the project. Your site has a lot of good info / details and looking forward to the CD so I can get started. Scot from US

By Scot

Hi Rado,

Yes! I did get the pdf files for the firebrick work.

I guess for the material list, I just count from your picture sequence, the number of bricks etc. that I will need. We definitely go with 3G MTo.

I had planned to build a strawbale house years ago and ended up using timbers due to the time factor. Strawbale structures are a lovely thing to look at and this oven will be a mini-project (that seems to be getting bigger and bigger ;) I will send photos once I get started. I am swamped right now with work and its really cutting into my pizza oven building time.

I look forward to making some bread and pizza wooden paddles as well. I have made laminated wood objects in the past and will keep you posted on this as well. Thank you for your interest.

My friend who has his oven up and running, was asking where he could get hardwood to burn. I read in a book you’re not supposed to burn pine (which in B.C. due to beetle killed forest, we have an abundance) I can get some birch but it takes two years to dry. What do you think about burning soft wood eg. dry pine or fir?

That’s it for today, time to head to the shop, talk to you soon.

By Urs

Hi Urs,

Aahh, I enjoy these topics. Strawbale homes and structures!

I use mostly hard wood, gum/eucalyptus, just because it’s plentiful where we live. These trees drop off their dry branches constantly which is a perfect fuel. In Europe I used mainly pine. Pine wood burns slightly more rapidly when compared with hard woods. But where it is coming from that pine and such soft wood isn’t suitable for wood fired ovens? Of course it is. I bet such tactics come from firewood suppliers and mainly those who supply oven kits plus firewood (because hard wood burns over longer time so to speak [btw nothing burns longer, though, not even candles -> all burns shorter and shorter in length:-)]). Therefore they can bring, buy, and resell, smaller volumes for the same money. Fair enough, but shame in the sense that pine grows faster too.

It is the same as with firebricks. Whoever buys from China and imports higher alumina content firebricks, more brittle, this is primarily because these are suitable for more application instances. Therefore from one product they can make potentially more. Also it is a lot cheaper to buy higher volume of the same one kind. And they spread out a bit misleading news to their customers. Over 25 years this constantly changes. Initially the beginners used to spread news about higher alumina content in brick that it better stores heat plus it conducts the heat within the clay body faster. Which is a marketing bullocks ;-). Achieved would be only extremely minor positive difference at the temperature level brick ovens actually will reach. More alumina in firebricks is mainly beneficial in different industrial usages, higher alumina content suits higher ‘Orton cone’ number in other words = e.g. ~ 40% alumina bricks withstand a lot higher heat in continuous usage, and that’s a much-much higher heat we are talking about here. On the other hand lower alumina content offers higher porosity in the brick, which positively absorbs the steam from under the dough, steam created between bread or pizza bases and the hot floor. It’s fain and easy to get used to any firebrick type, high or low alumina content, in relations to cooking.

With the timber type, you will be able to try it for yourself. If the material you use for manufacturing isn’t chemically treated before you get it, you could be a winner because any offcuts could used for cooking!

I would use the birch only in an indoor nice fireplace for those harmonious evenings!

Burning wood produces only that much of carbon dioxide how much the tree absorbed while growing. Equally if the branch happened to rot on teh ground, the same amount of carbon dioxide would be released. that’s why it’s sustainable.

Rado

By Rado

Congrats on an awesome site. I’ll be working on our second wood-fired oven for a restaurant in the next couple of months. I currently have one at our restaurant, and it is located outdoors. The new one will be at another restaurant but will be inside the restaurant’s air-conditioned kitchen. Putting aside building codes, do I need to have an exhaust hood over the oven if it is indoors?

Thanks for the info, and keep up the good work!

By Abe

Rado,

Love the site. I built a kit, barrel style oven and am working on retrofitting it. I tore down the chimney (which was located inside the oven door) and plugged the current flue. Now, I’m planning on building a hood/flue outside the oven door like this picture shows.

2 questions?

1) Does the inside oven door have to be arched?

2) I’ve got13″ from my oven door to the end of my slab, am I going to be able to build this hood or modify something similar?

Thanks,

Ryan Hayden

By Ryan Hayden

Hi Ryan,

Email us photo-s of the oven as it looks now. Where is it located, what is cooking the most?

1. The entrance can be rectangle as well. However, when it’s arched there is no need for the metal angle in the entry into the oven and arch is nice looking too. But still rectangle is very common and no problem with that.

2. So you have the 13 inches available in the front as it is now. Definitely you can create the hood vent in there now without extending towards the front. It can be done without create the extra room in the front if this box was made out of a nice thin material, like metal sheeting for instance – it can fit in with that measure and aesthetically suit also. Jig saws are also for metal and nice e.g. copper rivets are available in shops also. Can you visualize something like that?!

By Rado

Hi, Rado!

In regards of pine burning in pizza ovens or slow combustion stoves or fireplaces, the reason that you shouldn’t use it is because the pine resin in the smoke attaches itself to the chimney and if you do not clean it off regularly (which 99% of people won’t), you could have a chimney fire.

We have lost a few houses here in Canberra, due to chimney fires because we had large pine plantations and people used the pines for firewood.

I don’t believe that you would have problems with using pine in pizza ovens, but I would check the chimney, regularly for resin deposits.

By Joe Weinhardt

Thank you so much for re-sending, you have been awesome in getting back to me, very much appreciated! I apologize, you certainly have been a great support to me!

I received and successfully saved all three, thanks Rado.

I thought I may have run into a problem but the swishy oven doesn’t have an inner arch just outside the metal angle iron and oven entrance? I thought something didn’t look right but then looked at pictures Zg4, Zg7, Z01, Z02 & Z04 and they don’t appear to have an inner arch but the 3g-masterly-tail-oven design does?

The oven door to my oven is 10″h x 16 1/4″w – the oven entry is 11 1/4″ away from the decorative arch as I had it done. Do you think that will be ok?

I really hope this will be the last time I have to bother you Rado, I will send you pictures after completion and a Saskatchewan Roughrider T-shirt (our beloved football team – not soccer) for your support!

I am thinking I may have a real problem, the decorative arch is 15 1/2″ high that is why I am seeing so much of the angle iron at the oven entrance? As mentioned earlier the decorative arch is 11 1/4″ away from the oven entrance. We just got this new Mac computer and I am not sure how to attach pictures so will send 3 pictures to follow on three separate emails.

Thanks for your assistance Rado

By Brent

Hi Brent,

Keep it at that height it’s positive as it is now.

When it comes to this oven size I make the front wall decorative arch between 13″ and 14″ high. Basically it’s the same as the depth; which is this distance from the front wall to the oven entrance point. The extra inch or two as you already have it should not make much of a difference, even though your depth between the front wall (at the inside) and the oven entrance is those 11.25″ because as the hot air exits, after it turns/bends upward, it goes vertically. This should work, the measurements just fit in. At least, the extra height of the oven deco arch will keep this front arch-wall cooler while the flue is ~11 inches deep (the less spacious the flue is the higher temperature effects it.)

Where is the oven situated? It’s always easier for me to comment when I see images, often there are additional aspects to consider (and I enjoy that evidently), even though you describe what it is succinctly.

Yes the MTo designs do not have any metal angle in the entry into the oven. The arched entry allows that structurally (plus the arch looks nice, well at least by my eye.) It is really only what you fancy. 10″ high entrance is good/proper both for the rectangular entrance and also for the arched. However with the arched entry you can perfectly increase the ove-entrance to 11-1/2″ high, this is because the 1.5 inch difference applies only to a very small area, at the tip of the arch, whilst the sides exist much lower than those 10 inches. With such change the oven performance is totally the same, meaning brilliant, well no negative nor positive difference can be noticed at all. I build ovens with both 10″ and 11.5″ entries height. The width of the entrance isn’t that important. Just the height count (with experimenting; do not go lower than 7-1/2 inches rectangle.) The 11-1/4″ depth of the vent most probably will be fine. The 13″ depth I mention includes the reserve, to be 100% correct also/especially for indoors ovens. For one can be totally sure or pleased no anoying smoke gets into the room inside, so completely all exhaust fumes get dragged out.

Another way for how to fit in the flue box whilst still having the appropriate depth (between the front deco and the oven entrance), where there is not enough room, is to create the flue box out of a thinner material compared to any brick thickness. I have seen it done from copper sheets or old rustic corrugated iron sheets and it looked truly marvelous.

Just in case; if the oven was in an enclosed area and if you ever had any smoke inside issue you could totally improve it by adding length to the chimney which would create a draft which would pull in all the exhaust. but this is just in case, you should be all fine.

Can you email me photo-s of how you have it? I will have a look at it and comment more precisely.

By Rado

Hi Rado

I have a question.

In the ovens you build exhausts get out at the upper level of the entry door then going up in the chimney. Would it be possible to have the exhaust to the chimney in the back of the oven instead? Then air will get in at the entry door and exhausts at the back. Also then I suppose that it is important to get the ratio vault height exhaust height about 62% to 64%.

Do you see any disadvantages by having the exhaust at the back of the oven?

Cheers,

Torbjörn

By Torbjörn

Hi Torbjörn,

This is easy to calculate. But you would need to introduce draft in that chimney to make sure all hot fumes go in through its flue. And not only that, the chimney on the other side with the front opening, these two will certainly compete. The air circulation in such oven is slightly different to the safe front ‘inlet and exhaust in one’ system where there is no other way just one. If you wanted to be safe, so fumes travel out only via the chimney and also have the oven entrance opened, the system should look more as that of a opened fireplace. But with such the oven efficiency plus performance is a lot worst. It is better for saving the energy if the flue hole inside is positioned on a side, or at the back, at the hearth level, with separate fire-box (which has its fresh air inlet) on either side below a hearth level and simply channeling the heat in. Plus, the door closed while the oven is heated up or when it is being used for cooking or baking. You could regulate/experiment with the flue size in the design like this to have it tuned very well, meaning, to get the most from the heat. With the firing box on a side you will be ok. For what you described; if you had some bricks at home you can design and create such a system temporarily first, to test it, as to see how it behaves.

By Rado

Rado,

I received your plans quite some time ago, however due to work commitments I never get home enough to make it. Though I am adamant that this year I shall at least start it and fingers crossed, finish it too.

ANYWAY, I have been thinking about designs and modifications, so I’ve been scrolling through your plans and photos and trawling the net. My question is this: After the high temp cooking is done, (or have a low temp fire instead) is there any reason why you could not use a the chimney as a low temp smoker? If you added a hatch/door in the brickwork of the chimney for access and two horizontal steel rods inside to hang things off?

Just a thought.

Cheers.

Brendan

By BPOB

Brendan,

Yes there is this possibility to use the oven also for smoking of course. But keep in mind that after cooking, even when the fire goes down, there is still high heat in the oven, or there might be for a long while. So the smoker system design should take the higher temperature into consideration. Have you seen these: smoker system 1, smoker system 2, smoker system 3, smoker system 4? They all can easily use smoke channeling through the flue. Search the site also for smoking turkey or poultry, my hobby so to speak, it is totally lovely!

By Rado

Hey Rado,

I came across your site while searching for other forums relating to smoke issues. My brother and I built a wood fired pizza trailer last year but seem to have some major black smoke issues. The oven is enclosed in a 14′ trailer where the back door and service window remain open. The problem is that the smoke on a regular basic comes right out the front of the oven. We currently have a 6″ insulated flue about 4′ from the oven chimney. We might try a taller flue and have even considered getting an extractor fan to fix the problem but if you have any suggestions, we would be more than happy to hear from you.

I have attached a few pictures (into email) and I apologize for the quality since it was starting to get dark. We are going to try an extension on the flue tomorrow to see if that helps. I have also read about positive/negative airflow being an issue. Do you think an extra vent in the wall behind the oven would help any? We really are new to this and learning but would love to get this sorted before we get fired up again for the season. Thank you so much for your time! Looking forward to hearing from you.

By Sharalei

G’morning Sharalei,

My apology for delayed reply, this time I stayed working outdoors longer. From looking at the pictures you emailed it is clear that the vent/flue outside the entrance doesn’t collect all exhaust produced in the oven, both the smoke from the early firing stage before the smoke gas ignite also and then in same way also the hot air expelled from inside. the oven still performs all right, only the inconvenience of the smoke or the hot air gets close to the oven operator. I think this is the case you were thinking of also. Because currently the chimney pipe at the upper section in this vent passage is connected early (the vent could be twice as higher) and is if its diameter as is, the hot air isn’t dragged/moved upwards freely (these conditions slow it down), and that means the vent gets heated by the hot air faster, higher.

Do not create any additional vent in the back wall!

Two things can be done to fix/improve it. One would be a detachable extended chimney pipe to create a draft in the higher chimney which would make the original vent take in more. However I can imagine this could perhaps get a bit inconvenient if the oven was often on the move. So secondly, an option I would go for myself, is to make/extent the vent with a thin material towards the front; to create a hood which would be wider than the oven opening (about as wide as you can see the carbon coloring on above and around the entrance, meaning wider than the entrance) and about 6″ to 8 inches away from the original oven cast. This new hood/box would progress upwards and connect to the chimney. Or as I see on images in this situation it could pass by the cover next to the cast chimney, in the front, but it will remove the rest of the smoke. For instance a thin copper, etc., sheet will be easy to work with to cut it into the precise radius/lines, accurately as to copy the dome lines. The hood can be decorative too, not just for playing the practical function. In automotive shops they sell silicon in tube which withstands higher temperatures, which could be used as sealant between the dome wall and this new hood if it was necessary.

I would like to see how you made the adjustments on your mobile oven.

By Rado

Hi Rado,

A quick question about the flue box. I know the firebrick arch just outside of the oven uses refractory mortar to bind the firebricks together.

When building the flue box/chimney with house brick are you using a refractory mortar for the rest of the chimney as well? Or plain Type S mortar? Almost done.

By Guy Indelicato

Hi Rado, I have been enjoying your website for several years now, I have plans to purchase your building plans in the very near future and I am looking forward to building an oven in my back yard however, is it possible to make the interior larger?

I would like to know if there is a way to build the interior of the oven larger to have more floor space and a wider mouth opening to accommodate a larger pizza peel and full-size baking sheets, without compromising quality and functionality. I am in the process of making plans to build our wood-burning oven. I look forward to your response.

Kind regards, Joe.

By Joe

Hello Joe,

Yes of course it is possible to scale the oven. People do it once they have reasons. What do you intend to make in your oven after it’s built? Because, it is not needed too large internally, as the items put inside to be cooked or baked can be reloaded after a single heating. E.g. a few bread batches after one firing.

And specifically for pizza production with ongoing fire embers heat source going-on inside the oven here goes a practical example; let’s say a good quality pizza is done in ~2 minutes while another is being prepared, one is taken out as it’s done and the next one still uncooked is placed inside to be cooked fully. The logic of it; how many pizzas can you prepare in 2 minutes as the only one oven operator at that time while the previous pizza is being baked? At 2 minutes each without pauses as they say; that system produces many pizzas – 30 pizzas in an hour yield. At 3 minutes cooking time per pizzas the gain comes to 20 pizzas per hour (still hugely high for off-peak hours @ 10 to 15 bucks per pizza).

But anyway; it is very easy to change the size just by adding in or taking off a firebrick or two from a side, and then adjust all around and under to the new size change. Structurally reflecting, apart these new dimensions, all remaining matters stay the same.

The width of the entrance can be changed as well. Leave the entry height of it as is if practically fits fine and if it’s a wood fired oven of the same style.

Warm regards,

Rado

By Rado

Hello Guy,

Thank you for the question. In here when it comes to working on the hood and the chimney using the normal common house-bricks, I add the builders lime into this mortar. So practically speaking; for the same cement part quantity, into this mortar mix I add in addition (plus) the equal amount of lime. The mortar with lime added to it sets and cures slightly longer so it’s comfortable to work with especially when working while standing higher on a scaffolding or going up/down a ladder. A better quality cement as the only sand bonding agent in the mortar will work too in making this part.

By Rado

Hey Rado,

Looking to build my first starting in the next several days. If looking at the oven door, it appears (based on estimating the brick at about 9″) that the depth of the smoke box (between arches) is about 9 inches. But I thought I read that you suggest 13″. What am I missing?

By Brian

Brian,

Please look at the 1st image; the hood depth measurement goes from the first firebrick arch, it is 13 inches deep, or more deep (not less). The second arch which is already in some higher level is the part of the actual hot air passage structure, basically part of the hood and later chimney. The fumes always exit in the bent-upwards radius and nicely bypass along the 2nd arch as depicted on this second image. This way 100% of all fumes and smoke-exhaust travels upwards inside the chimney.

By Rado

One of our tenants is opening a restaurant. He wishes to do BBQ lamb, and chickens.

We understood the hood needs to cover his activity. The question is what size of a chimney he needs to install to get a proper Chimney draft or draught function. Distance to top of building point from that floor level is about 12 meters high.

Thanks

By LOUIS BATSHONE

Thanks for the brick hood size information and the flue vent measurements. Very useful.

By Chris

Hi Rado,

I intend to build an indoor Pizza oven (Barrel style) in my kitchen. My given concrete slab area is very small: it is 100cm wide x 80cm deep and I intend to use gas for the fire. The front needs to be on the 100 cm edge. Given these problematic measurements, do you think it is feasible to build such oven? These measurements need to include the oven heat insulation thickness. What should be the thinnest wall brick I should use for the walls to maximize the cooking area? How much cooking space will be remaining?

In addition, the back of the oven lean against an exterior wall, from where I intend to lead the chimney horizontally through it to clear the gases. Any comments or suggestions are very welcome. Thanks! Giyora.

By Giyora

I followed the flue sizing guidelines you laid out and wanted to say thanks.

As it is an indoors oven it was vital that there was no smoke even at startup. Result is a perfect draw with a 170mm Diameter and 2.4m Long chimney. Thanks heaps for putting this great page together.

I ended up building to standard bricks away from the dome entrance which is 440mm

By Brendan

Hello! & your web~ site has great readings.

I’m building a {I.D.} 40″ Diameter Fire Brick outdoor oven later this year. How big should my Pizza Oven door be? W X H The door will be Stainless Steel with a little Formica Window in the middle & a thermometer installed. The door will be insulated with Fire / Heat proof material. The Handles are made from old Masonry Trowels.

Also: The chimney will be made of Rust Colored Roman Styled Bricks 1″T X 14″ L X 4″ W. There will be a Clay liner on the inside. How high can I make this Chimney?

Thanks for your time. Mike L.

By Mike Lashinsky